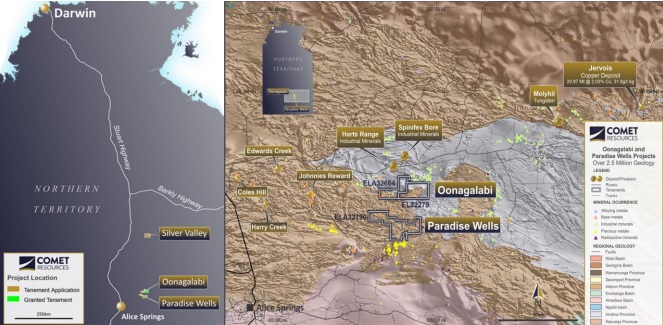

HIGHLY PROSPECTIVE COPPER-GOLD-ZINC-SILVER-LEAD ASSETS IN THE NORTHERN TERRITORY

The Portfolio of Northern Territory exploration licenses and exploration license applications covers an area of

approximately 840km2.

Background

Although historical exploration results were indicative of near surface gold and copper mineralisation, very limited modern exploration has occurred. Comet plans to utilise modern exploration techniques to advance the scale of known Mineralisation, especially where known geophysical and geochemical anomalies exist that have not been comprehensively drill tested.

Oonagalabi Project

The Oonagalabi Project exploration licence and exploration license application (EL32279 and ELA32664) contains ~1.7km of outcropping copper, zinc and lead mineralisation, hosted in anthophyllite-cordierite and forsterite marble sitting within the Strangways Metamorphic Complex. The mineralised Oonagalabi Formation represents a very similar geological setting as other known copper deposits in the region, including KGL Resources Jervois Copper Project, which is host to a 20.97 million tonne JORC resource at 2.03% copper and 31.9g/t silver, for 426,200 tonnes of contained copper and 21.4 million ounces of silver (see KGL Resources ASX announcement 15 September 2020).

Paradise Well

The Paradise Well Copper-Gold Prospect exploration licence application (ELA32190) sits approximately 10km due south of the Oonagalabi exploration licence and covers an area of ~250km2. Two prospects have been identified on the tenement through historical rock chip sampling programs which returned copper grades of up to 8.88% copper (Manny Prospect) and copper/gold rock chips of 6.24% copper and 2.15g/t gold (New Paradise Well Prospect). Neither prospect has been subject to ground geophysics or drill testing and presents an opportunity for Comet to follow up historical work with a systematic program geophysics to identify drill targets.

Silver Valley

The Silver Valley Copper-Gold-Silver-Lead exploration licence application (ELA32241) sits approximately 300km north of the Oonagalabi Project exploration licence and sits within the Davenport Province, a folded succession of Paleoproterozoic shallow marine sedimentary rocks and volcanic units. Four outcropping lead / silver bearing quartz veins, which have been worked by historical pits and shafts, are present within the tenement. Key prospects include the Chablo Prospect which is prospective for lead, silver, copper and gold.

A sample of 130 rock chip assays collected produced results up to 554 g/t silver, 20% lead, 11.9% copper and 2 g/t gold.